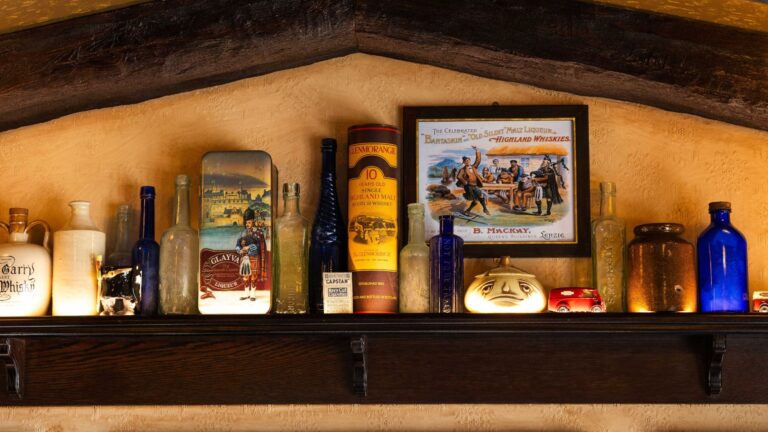

In Gary Altenburg’s backyard sits a small Irish-themed pub named T. O’Loughlin’s. With a beautifully crafted wooden interior – complete with leather bar stools, a fire burning in the corner and Guiness on tap – it has all the warmth and ambience of a pub in the middle of Dublin, only on a much smaller scale. It is also the first in the line of what has become a very popular side business for MWF Manufacturing.

Located in Belfast, MWF Manufacturing has become a local leader in joinery manufacturing. Mr Altenburg and his wife Charlotte bought the business in 2002 with their sights firmly set on cornering the high-end bespoke joinery market. A joiner by trade, Mr Altenburg has also become known for his ability to take a concept and run with it – often starting out with only a few sketches on a piece of paper.

“When I first started out in Christchurch, I worked with Mark White who had a very different mindset around our industry. At the time he was doing a lot of film sets and instead of working off architectural plans, he would just do some sketches and then turn them into something solid. I enjoyed woodwork and always had a fascination with building stuff, but being able to turn drawings into reality really sparked my passion for the industry. We’ve had a number of options to just make widgets, but I wouldn’t get out of bed for that. I’ve always wanted the variety and the challenge of being able to create something from a sketch or an idea.”

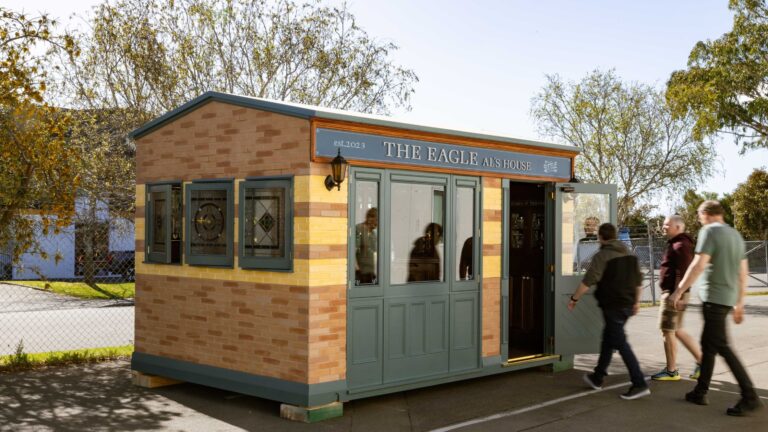

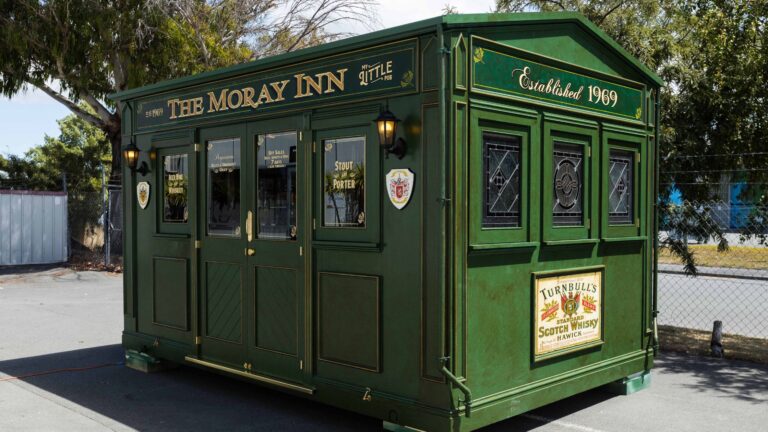

Over a decade ago MWF Manufacturing and commercial designers Element 17 had been successfully building full pubs for breweries. When the lockdown hit in 2020 the idea resurfaced. “Initially I had been thinking about tiny homes, then COVID-19 hit and everyone started doing them, so we thought why not tiny pubs and started work on our first one.”

The first My Little Pub took 1800 hours to complete and is named T. O’Loughlin’s after Mr Altenburg’s father-in-law, an Irishman. The family name is just the start of the level of detail in the pubs that really captures the heartstrings – from the black and white family photos to custom clocks and stained-glass windows, and very specific memorabilia sourced or reproduced by MWF Manufacturing.

The pubs cost from $100,000 to over double that, depending on the fit-out and extras, with a lower price-point option to be launched later in the year. And the orders come from people you might least expect. “We sold our biggest pub, fully optioned to a young couple with kids. We’ve also had a mum with young children who bought one as a tribute to her late husband. My Little Pubs create a strong emotional connection that is hard to understand unless you sit in one – or visit a pub in Ireland. It’s about creating an environment to bring people together to chat and share a few yarns which helps eliminate some of the luggage they carry around every day. All I see with our customers are smiles.”

Three years on, MWF Manufacturing are on track to complete 20 pubs by the end of this year and 40 next year. Currently all of the pubs have found homes in New Zealand, with the company looking to start exporting by the start of 2025. The challenge is how that fits with the current bespoke offering, where every little pub is personally delivered. “The enquiries from offshore are far greater than in New Zealand. But the challenge is how to make them as a kitset that can be shipped in a container, without losing the level of detail we have become known for. The dream for this is to be exporting around the world.”

For every pub that is sold, the profit is invested back into the wider company, with a focus on automation and streamlining systems and procedures, such as utilising customised AI software for a lot of the administration as well as integration into new design software.

As well as My Little Pubs, the company also has a number of other business units, including acoustic panels, Smith’s Kitchens – a joint venture with Smith’s City, and a new outdoor furniture range due to be launched. “I’ve got 14 pellets of fabric in the factory because I want to launch an outdoor furniture range this summer,” says Mr Altenburg. “There’s a lot of disposable products out there, so I wanted to do something solid, long-lasting and New Zealand made. Normally people would do a design and a project scope, but I’ve gone to my team with a drawing and some fabric and said: ‘what do you reckon?’ I love taking ideas and turning them into cool stuff in a way that is viable.”

It’s this creativity that has made MWF Manufacturing a sought-after place to work. The team is currently comprised of 38 staff, including four apprentices – a very deliberate move to best position the company for the future. “Everyone is a tradesperson or an apprentice. We’ve set a goal for our apprentices to be up on the podium as the best. We’re lucky because we get the best people from the trade courses because we’re an interesting place to work. We’re playing the long-game to create a highly-skilled stable staff-base.”

Looking ahead, Mr Altenburg says the company is not immune to the impact of the recession but has been able to draw on the experience of surviving the earthquakes and COVID-19 to be able to weather the storm. “It’s very lonely and bloody tough to be in business. I respect anyone that has been in business for ten years that can raise a smile – they’ve definitely done the hard yards. But we’ve been here before, so we know exactly what we need to do in terms of strategy, finance, people, sales and so on. It’s an opportunity for me to roll up my sleeves and get stuck in. And I’ve got a few ideas on how I can do that.”